We pride ourselves on the close working relationship we foster with our customers who are able to depend on our reliable service and solid expertise. Our employee’s know-how, a state-of-the-art machine park , our comprehensive knowledge of processing technologies and the experience we have amassed delivering numerous projects are all guarantors of our products’ success.

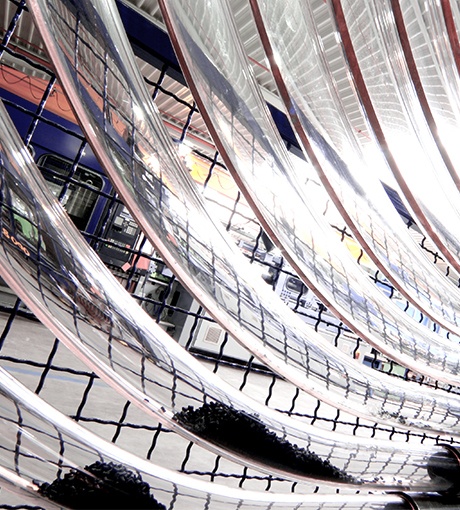

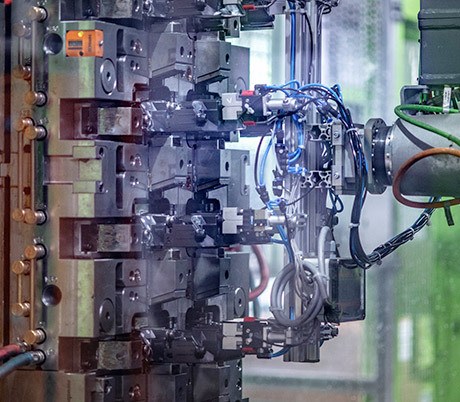

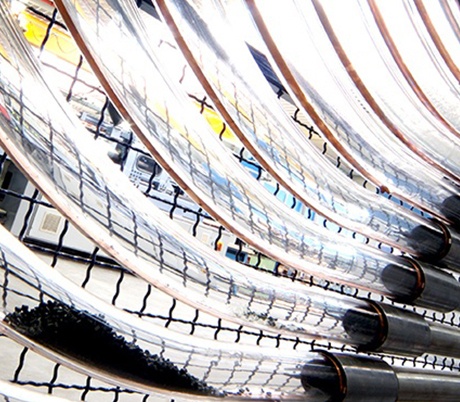

We process virtually any type of commonly used thermoplastic into complex engineered moulded parts on our 60 injection moulding machines with clamping forces of between 10t to 650t.

- Material selection

- Process development and technology development

- Sample and prototype production

- Resource allocation

- Automation

- Central material supply with batch traceability

- Manufacture of individual components and assembly

- Quality assurance and documentation

We mould our customers’ ideas into shape.